|

|

|

2nd IWCFD 2007 |  |

2nd International Workshop on Crystallization Filtration and Drying

|

|

|

|

Chemical Weekly Report on 2nd WFCFD

| OVING FROM PRODUCTS TO SOLUTIONS | Academia, researchers and industry (chemical, pharmaceutical and allied) interaction besides partnership with the equipment manufacturers and service providers, reemerged as 2nd International Workshop on Crystallization, Filtration and Drying featuring basic theory, practice and integrated solutions to the problems posed by the end users, recounts Dr.K.S.MURTHY, Technical Consultant, Mumbai.

| UICT ranks high amongst the Chemical Engineering Schools in India and in terms of undergraduate teaching, research publications in international peer reviewed journals and consultation to industry. It maintains its apex position amongst the numerous contemporary institutions. This has been endorsed by the recent survey carried out by Prof Jude Sommerfeld of Georgia Institute of Technology, which revealed that UICT continues to achieve the number one position in the country based on the criteria of the number of international publications despite the number two position over the last 43 years has been changing from one institute to another and it is always a distant second. Though, there is no way of ranking the connectivity with the industry, the income from research projects compared to the moneys received from the government is 4:1 and the second best institute is significantly behind (0.25:1).

| In view of the above, it is indeed a welcome feature that World Forum on Crystallization, Filtration and Drying (WFCFD) launched by UICT in collaboration with the Department of Chemical Engineering has embarked yet another international workshop during 22-24 February 2007 in the renovated K. Venkataraman Auditorium, Mumbai, incorporating further technical developments consequent to the successful outcome of the first workshop held in February 2006. Dr. M. Sriram ably convened the proceedings.

| Prof. G. D. Yadav, Head of Chemical Engineering Department is a dynamic personality, who garnered sources and resources for effecting changes in UICT and for its advancement. He said that the basic unit operations Crystallization, Filtration and Drying are important particularly in pharmaceutical industry since the product is not accepted if it does not conform to proper density, crystal size and size distribution. Government of Maharashtra commissioned a grant of Rs.2 crores under Rajiv Gandhi Foundation for Science and Technology for doing research work under the supervision of Prof. B. N. Thorat in the field of drying, like food particles, fish etc. for benefiting rural people. In the world of nano-materials, crystallization assumes significance and design of equipment requires knowledge of fundamental science. Prof. Arun S. Mujumdar the driving force behind the drying activities at UICT, Prof. Thorat (chief architect) and Prof. A. B. Pandit spearheaded this conference and workshop.

| Prof. Mujumdar (Founding Chairman of the WFCFD and respected worldwide as the Drying-Guru) of National University of Singapore said that the objective of this Forum is to make know-how and knowledge available as widely as possible and encourage contributions from institutions and industry. Having lectured in about 40 countries, he observed that the level of interest in India is more like that in China about two decades ago. He began the well known IDS international conference series in drying in 1978 at McGill University Montreal, Canada, when people opined it was not an opportune time as drying R&D was not being done those days anywhere in the western world. Yet, he had a differing vision for the need for drying R&D and he carried on regardless since drying entailed energy intensive processes and in order to reduce energy consumption in paper making (massive dehydration operation), which entails in simple terms 1 kg fibre added to almost 200 kg water followed by processes designed to getting rid of all this massive amount of water. This is very expensive and the cost is mainly due to drying. The process entails a sort of filtration for mechanically dewatering, followed by drying, and energy consumption is 35-40% making the cost of paper almost proportional to the cost of energy. This was a turning point for him to enter into the field of drying to improve the process and he soon discovered that the problem is universal for all commodities such as agricultural products, food products, ceramics, pharmaceuticals, chemicals etc. Additionally, drying controls dried product quality and hence the operation must be carried out with care.

| Drying is a complex and potential area wherein one can do serious R&D. Scale-up has to be done empirical; however we wish to improve the component of knowledge and know-how. Thus, efforts made in this direction led to about 55 countries participating in the international drying conferences as well as regional (10) conferences including China where parallel conferences were being organized two decades ago in the 90s, Chinese government declared drying as one of the strategic areas of research and provided matching funding. Besides the massive Handbook of industrial drying in Chinese, a Journal exclusively devoted to drying equipment has been published for over a decade..

| Prof. Mujumdar concluded that the other physical operations of Crystallization and Filtration often go together with drying thereby evolving the CFD concept. This combination generates synergy and one may not optimize just dryers alone but optimize drying system like the other two operations. It is important to look at all the three operations equally in the industry except paper and textile where there is no crystallization, but it is necessary in chemical and pharmaceutical processes. World-class speakers in these fields presented their ideas and shared their knowledge with the participants.

| | Inaugural address | Mr. D. P. Misra, Director General, Indian Chemical Council said that CFD is close to his heart having worked on nonferrous metallurgical project for the expansion of Hindusthan Zinc Limited.

| ICC offers assistance to the manufacturers and service providers to the chemical industry segments like refining, petrochemicals, fertilizers, heavy inorganic and organic chemicals, pharma biotech, bulk drugs, paints etc, which is valued about $150 billion. Significant investments are further going on to the tune of 40-50 billion. Expansion is on in bauxite ore besides zinc and coalmine and for energy security, coal is the biggest asset. Coal quality is such that all the equipment should be in place and the demand for such equipment is enough. The whole range for separation of minerals requires the use of sophisticated solid-liquid equipment. India has large deposits of minerals both in the Eastern coast and Southern coast of Kerala where separation of heavy minerals like aluminite, monozite etc are done and monozite would be used for the manufacture of Thorium intended for nuclear reactors.

| Pharma, biotech, paints, adhesives and emulsions etc require sophisticated use of solid-liquid equipment. Advent of Nanotechnology increases the requirement of sophisticated equipment for the manufacture of nanoproducts. Use of the equipments in fertilizers e.g. phosphatic fertilizer plant (P2O5 3000 tons/day) requires the use of huge belt filters from the fusion pan filters used earlier. Requirement of this equipment is enormous and one finds a gap in the counter design of the equipment by our manufacturers. Sophisticated equipment with requirement of minimum energy is the need of the hour.

| While discussing various types of crystallizers like agitated tanks, vacuum crystallizers etc. it is worthwhile to pay attention to how the Indian equipment manufacturers are able to design and manufacture and also the design for various types of agitators. Development for the manufacture of sonocrystallizers is on.

| The crystallized products need to be filtered. Filtration has extensive use in various areas. The development in leaching of non-crystalline requires 3-stage CCD washing incorporating ground filter (belt discharge type). Whereas the number of manufacturers has come down, the requirement of filters is growing. Nutsch filter, leaf filter, Hi-bar, disc filter (ceramic type as well), Cuno filter (fundabac) etc. are used in respective areas. The empirical license is an optimum filter in view of energy. Media, material of construction and availability are to be considered and the practical size (studied from nano to 0.1-1000 micron) while selecting the equipment and process.

| The filtered products need to be dried and there are about 100 commercial different types of dryers available for about 50,000 types of uses. Energy input is the key to this operation. Commonly available dryers are spray, paddle, rotary, flash etc. Pharma requires sophisticated drying like vacuum drying, infrared dryers, and fluid bed dryers (also agitated FBD). Mr. Misra expressed the hope that this conference would discuss the issues related to the design, selection and the use of variety of solid-liquid equipments.

| | Valedictory Address by Prof J.B.Joshi | Having complemented with masterly acumen in the question-answer discussion with the delegates in the finale, Prof Joshi remarked that in the reactor design and separation processes, although one endeavors to extract last 1% particularly in distillation, absorption and evaporation similar attention is not given to crystallization, filtration and drying wherein huge losses of up to 30% are encountered. Thus, it is amazing that researchers have been solving the problems of 1% loss in reactors and distillation but not on the CFD front. However, with the involvement of stalwarts like Prof Mujumdar, Prof Doherty et al who are working on these physical problems, the entire chemical engineering community as well as industry would be benefited. WFCFD series is becoming a regular feature since the requirement of the industry is huge and the show will go on in the years to come.

| Prof Joshi lauded the organizers for devoting time and conducting the workshop in a fitting manner on a positive note of academic performance on the research projects, which are difficult subjects. He invited the delegates to interact with faculty and see for themselves UICT facilities beyond crystallization, filtration and drying and problem solving strength. He concluded that by interacting with the institution, the overall benefits are attractive viz. with a payment of Re.1 for research, one gains Rs.100 as return on investment.

| The distinguished speakers fielded the numerous and challenging industry-oriented problems posed by the delegates seeking viable solutions, shared their expertise and offered advice at the end of each session in the open forum held at the end of each long day. Following was the Technical Program of the 2nd WFCFD.

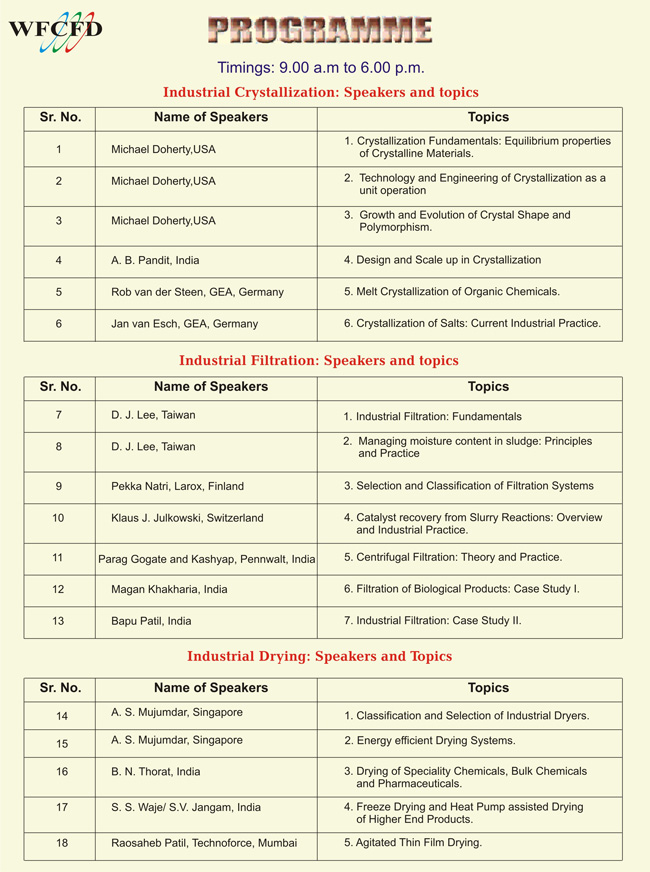

| | I. Industrial Crystallization | | Speaker | Institution / Organisation | Topic | Professor

Michael F Doherty | Department of Chemical Engineering,

University of California,

Santa Barbara,

USA | 1. Fundamentals: Equilibrium properties of crystalline materials

2. Synthesis of crystallization process flow sheets

3. Growth models and evolution of crystal shape | | Rob van der Steen | GEA

Niro Process Technology

The Netherlands | Suspension based melt crystallization: Process principles, typical process design and features | | Professor A.B.Pandit | Dept of Chemical Engineering, UICT | Engineering design and scale up of crystallization | | Jan Van Esch | GEA Messo GmbH

Germany | Conceptual process design:

Situation of plant construction in industrial mass crystallization |

| | II. Industrial Filtration | Professor

Duu-Jong Lee | Department of Chemical Engineering, National

Taiwan University, Taipei | 1. Filtration theory

2. Managing moisture content in sludge fundamentals and applications | | Pekka Natri | Larox Corporation,

Finland | Selection of filtration systems | | Bapu Patel | BASP Industries

Thane. | Industrial filtration:

Case studies | | Parag R Gogate | Department of Chemical Engineering, UICT | Centrifugal separation:

Theory and practice | | Klaus J Julkowski | Dr.M AG

Switzerland | Catalyst recovery from slurry reactions:

Overview and industrial practice | | Magan Khakharia | Microfilt,

Vikhroli, Mumbai | Filtration of biological solutions –

Case study |

| | II. Industrial Drying | Professor

A.S.Mujumdar | Mechanical Engineering

National University of Singapore | 1. Principles of drying

2. Classification and selection of dryer

3.Energy aspects in Drying | | Sunil S.Waje | Department of Chemical Engineering, UICT | Freeze drying:

Principles and Case studies | | Sachin V.Jangam | Department of Chemical Engineering, UICT | Heat pump assisted drying of higher end products | | Professor B.N.Thorat | Department of Chemical Engineering, UICT | Drying of specialty chemicals, bulk chemicals and pharmaceuticals |

| The compendium included lecture notes of the topics presented by the renowned speakers from all over the world besides young aspiring research scholars as noted in the table above.

| |

|

|

|

|